Years ago, we learned our lesson on overhead duct leaks.

The most popular U.S.-manufactured solution for mist collection ducting systems utilizes rolled-end duct. For oil, mist, and coolant collection, that’s a potential problem.

One day, we received a phone call from an overseas factory. They had installed rolled-end duct on a mist collection system to capture machine lubricant mist, and the overhead duct was dripping on workers and equipment.

Rolled-edge ducts create headaches for mist system installers and users.

The issue: With mist collection duct, every clamp connection – every pipe and fitting – needs a gasket to prevent leaks.

And at this factory, we discovered that the contractor had not installed the gaskets properly.

Proper installation may have been nearly impossible. The gaskets that were supplied were very difficult to install on large-diameter duct. And, when installing gaskets on overhead duct, you may be working on a 30-foot lift, trying to hold the gasket in place while installing the clamp, without moving any part of the gasket.

While the gasket can be secured with adhesive or silicon, that’s less than ideal; if the duct is oily, the adhesive won’t hold, and, with silicone, it makes the duct difficult to disassemble.

Consequently, with rolled-end ducting, each clamp creates a potential point of leakage. The gasket is difficult to install, which raises the chances of a leak.

And as already admitted by the manufacturers, the rolled end connections leak air. So, liquids will find their way out of the connections.

A Better Design for Mist Collection Ducting

Mist and lubricant collection systems require a different duct design to eliminate dripping, and protect workers and equipment.

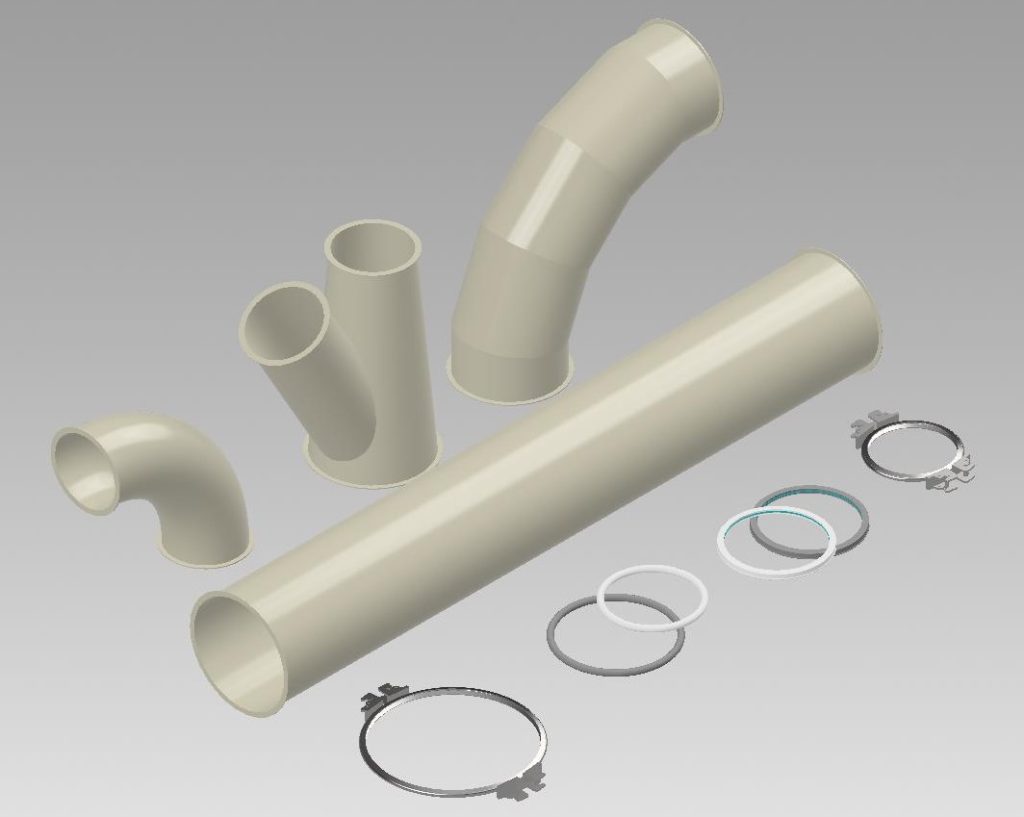

Our Noro duct product line features a flat flange end. The gasket is grooved, which allows it to stay in place over the flat flange. Everything is much easier to assemble. And, with flat flange clamped to flat flange, with a gasket sandwiched in the middle, you have a perfectly sealed connection.

Advantages of Noro tubing:

- Solidly Connected – Noro duct does not leak air, and the flat flange ends prevent fluid leaks.

- Energy Efficient – Noro tubing is the most energy-efficient ducting available on the market today.

- More Robust – The material is 50% thicker than the typical U.S. manufacturer’s duct, allowing for longer span lengths and ensuring years of dependable operation.

- Better Looking – Powder-coated metal improves aesthetics and ensures durability.

- A Wider Range of Applications – With an airtight design, Noro tubing can be used for both pressure (pneumatic conveying) and vacuum (environmental control) systems.

Oil, lubricant, and mist collection systems are essential processes in an operation, and each system must be robustly designed and precisely installed. Noro tubing is simply the most effective choice for these applications.

3D Digital Designs for Easy Installation

To further simplify installation, we can design your system digitally. With a short visit to your facility, we create a three-dimensional image of your process, noting the location of equipment, working paths, and any special considerations.

From there, our systems design is completed offsite. Our clients are actively involved in the design, and make modifications and improvements before the system is ordered.

When the system arrives on-site, it’s complete and ready for a hassle-free installation. Overages and underages are minimized, and contractors don’t need to wait for last-minute additional parts to start constructing.

Our approach reduces costs, improves operational results, and eliminates cost escalation due to change orders from contractors. To learn more about our mist system ducting – send us a message.